Company History

The company was found in 1994 under the name Metal Progres Strakonice spol. s.r.o. ( MP). Since 1996, after taking 98% stake in the company, it became the property of the French company, Florence et Peillon, based in Lyon. In 1997, the company purchased the remaining shares from MP parent company, so its share rose to 100%. Florence et Peillon company belonged until 2000 to the Suez group. In 2000 the Florence et Peillon (Faramet) was sold to European group EUROALCOM, which brought together a total of 25 companies of similar orientation in Europe and beyond with the total number of employees exceeding 4000. In December 2002, the shares transferred to the MPS Brabant Alucast Products. In 2003 it became a subsidiary of Brabant Alucast International B.V. headquartered in the Netherlands. MP is one of six companies of Brabant Group. Its branches are in the Netherlands, Germany, Italy and Brazil. In 2010 within title unification, the company was renamed to the Brabant Alucast Czech, Strakonice Site Ltd.

Company characteristics

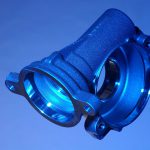

The company has five business activities, the most important and the most significant is the production and machining of castings made of lightweight aluminium alloys, primarily for the automotive industry. Manufacturing takes place by precision casting under high pressure on modern machines. Subsequently, the castings undergo surface treatment or more precisely – further mechanical machining.

The entire production unit is designed to be very flexible, able to react quickly to any customer requirements. The company is divided into four operations – BAC1, BAC2, BAC3 and BAC4. BAC1 operation is focused on the production of small series production (about 100 000 pcs / year), while the fully automated operation BAC2 is designed for large series production of complicated castings. Both plants deal with high-pressure casting, and there is a total of 13 machine with a clamping force ranging from 250 to 1100 tons. BAC3 operation focuses on precision machining using Chiron and Mori Seiki CNC machines. Operation BAC4 deals with low-pressure casting on 3 low-pressure LPM machines.

The company is engaged in the manufacture and supply of parts for the automotive industry (99%). Of the total production of the company, 75% is exported to developed automotive markets. The main customers include the French, Austrian and Dutch companies.

To date, the company employs 350 employees. Its annual turnover reaches CZK 500 million.