APQP

Quality driven thinking begins at an early stage with planning of a new project. During this phase, we work very closely with our customers. Our goal is to clarify not only unmanufacturable but also, qualitatively manufacturable requirements for parts.

Pre-series

During the planning phase of process and design of tools our strategy is to offer quality solutions for all issues.

PPAP

The starting point for implementing each product is to continuously monitor each step of the process. Starting with incoming materials inspection and ending with final inspection of the finished product.

SOP

Our team of quality check is in conjunction with customers throughout Europe during each process step. This communication is done on a daily basis in languages: Czech, English, German and also French.

Outside the numerous project-specific process controls (such as dimensional inspection, pressure testing) we use standard gauges:

For the casting process:

– Spectrum Analyzer

– Gauge for gases in melt

– Radioscopic device (Seifert X-Cube)

– Endoscope

– Ultrasonic gauge

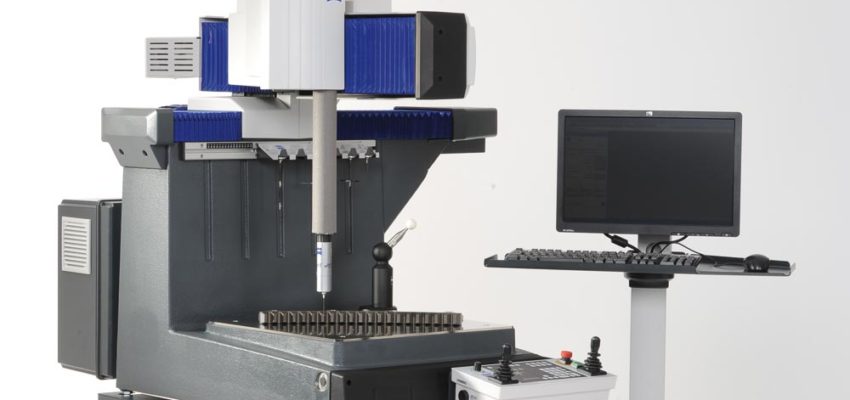

For the machining process:

– Coordinate measuring device (2x Wenzel LH87, 4x Zeiss DuraMax)

– Conturograph

– Profile-projector

– Roughness measurements (2 devices)

Our orientation towards our customers is mainly in the field of process and quality but also in the context of continuous improvement. The results of our work, due to the qualitative goals and goals for the environment, are several times defended quality certificates ISO / TS 16949 and ecology certificates ISO 14001.